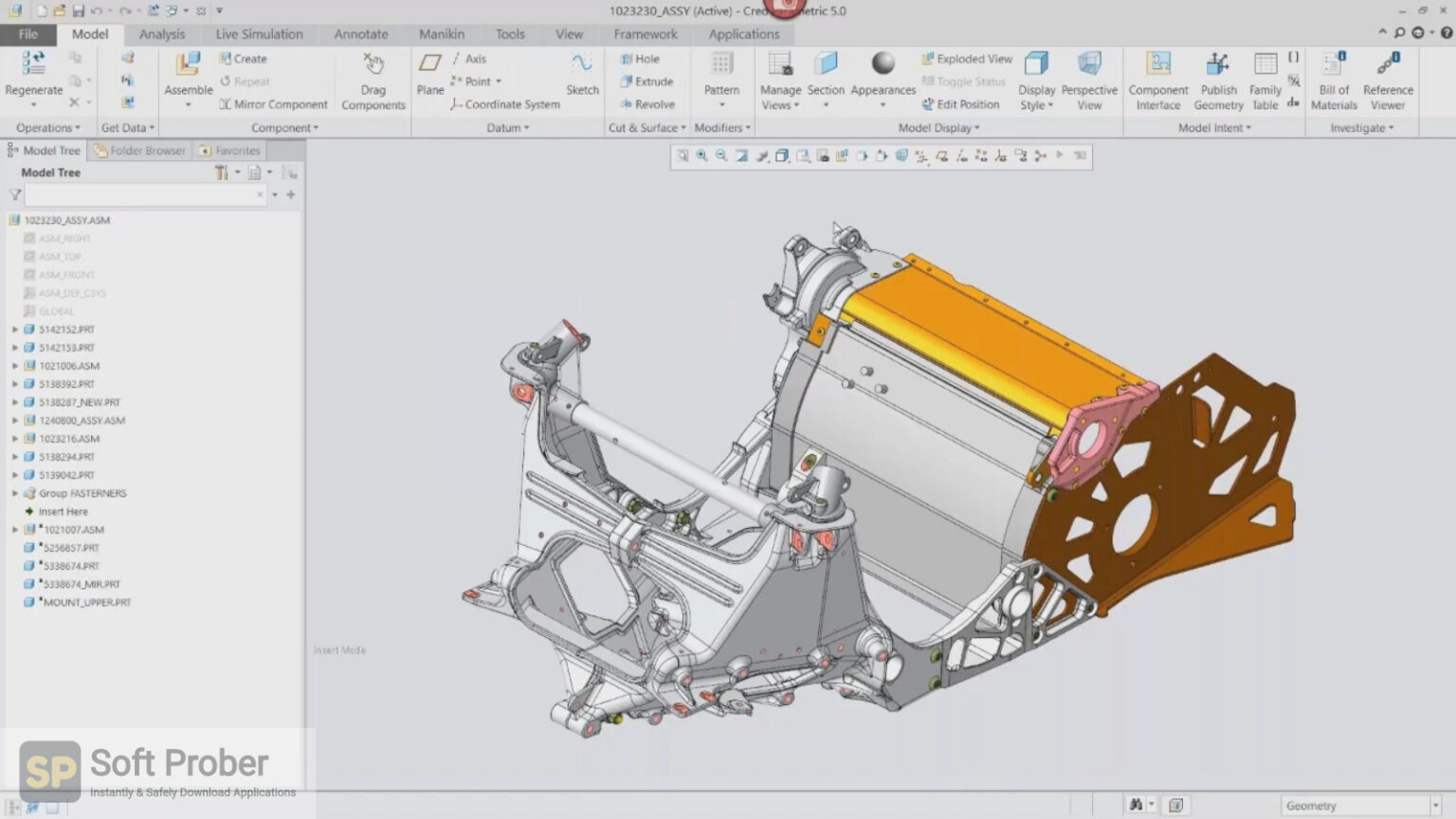

The software has several graphics display options. You’ll be able to apply the same editing methods to imported geometry. You may also use the Move-From, Move -To command to use a surface as the destination direction, then move your geometry closer or farther from the reference plane by a specific distance.Ĭreo Direct doesn’t read native CAD files from PTC’s rivals, but it lets you import neutral CAD formats (IGES, STEP, STL, and a few others). This allows you to, for instance, move a boss two inches away from its current position along a certain edge, making sure your geometry remains in perfect alignment as it moves. For greater control, you have the option to reposition the Copilot’s origin to a desired reference point. For simple movement of geometry, you can click on the face or feature and drag it to a new position.

For operations that require precision, you can use the numeric entry (say, to extrude a profile to 5 inch height). The part modeling environment is quite robust. At launch, you’ll be prompted to choose between part and assembly modeling environment.

Whereas Creo Elements/Direct doesn’t make a distinction between part and assembly modeling environments (you can model more than one independent part in the same window to create your assembly), Creo Direct does distinguishes the two. It uses a similar Copilot (a drag handle with directional arrows and rotation guides) to let you push, pull, and rotate faces and features to swiftly create geometric shapes of your design concepts. But the time frame for that is indefinite, definitely not something that’ll happen in the next release.Ĭreo Direct 1.0 is a robust part and assembly modeler. This will eventually elevate Creo Direct to a commercial-class direct modeler, adoptable for those using Creo Elements/Direct Modeler. PTC’s long-term plan is to continue adding features to Creo Direct over time.

0 kommentar(er)

0 kommentar(er)